We propose optimal systems to realize the production equipment and systems for heat exchanger fins that meet your requirements.

With the addition of HIDAKA's unique system control technology to the fin production equipment technology cultivated over many years, the system delivers even higher levels of performance in terms of product quality, production capacity, efficiency, and management.

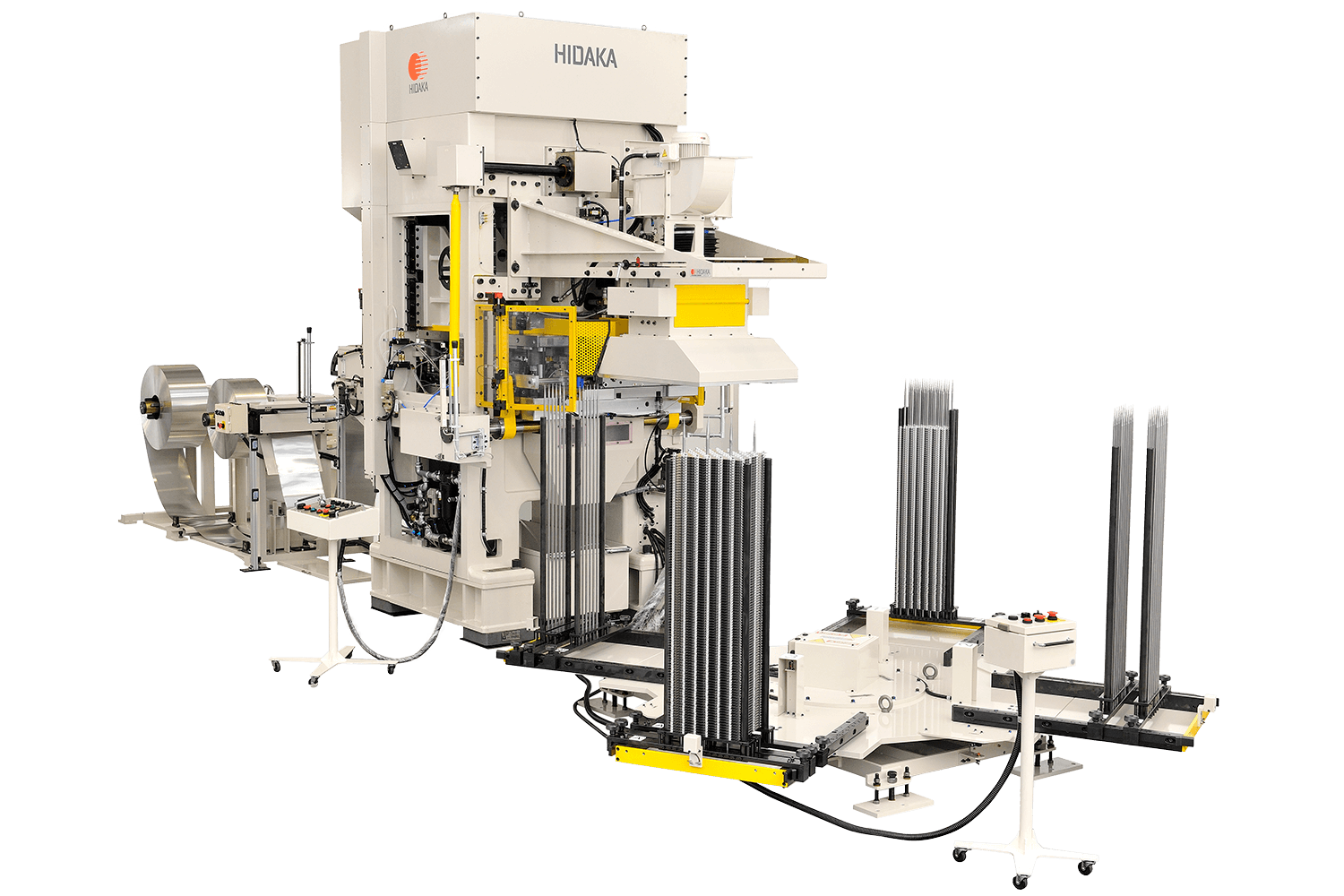

High Speed Line

HIDAKA's flagship model that enables ultra high-speed metal forming.

High efficiency—To meet this demand, HIDAKA, with its extensive experience and technology in heat exchanger fin production systems, offers the ultra-high-speed fin press AT-80H.

This model allows you to realize highly efficient production systems while offering a variety of benefits.

Product Specifications

AT-80H Fin Press General Specifications

- Capacity: 800 kN

- Stroke length:30mm

- Number of strokes:200-600SPM *1

- Slide adjust:35mm

- Die height:295mm

- Slide open:90mm

- Slide:1100×1400

- Bolster:1200×1670×140t *1

- Hitch feeder and gripper feeder

- Stamping oil supply system

- Stamping oil lubrication system

- Crank angle meter, SPM indicator, die height indicator

- Electronic cam control

- Load monitor(2ch/4ch *2)

- Anti-vibration system

- Control panel with large HMI

- Main unit handheld control panel with HMI

- Various safety equipment

- Output of various equipment operation data and maintenance data

*1: Subject to the specifications of the installed die.

*2: 4-channel type is optional.

Uncoiler High-Speed Material Feeder

- Material coil outer diameter: 1200 mm max.

- Material coil weight: 2 tons max.

- Material coil mounting: Single/double specifications are available.

For other special specifications, please contact us.

Fin Stacking Device

- 2-stage/3-stage swivel, fin stacking type

- Trolley-type fin stacking type

For other special specifications, please contact us.

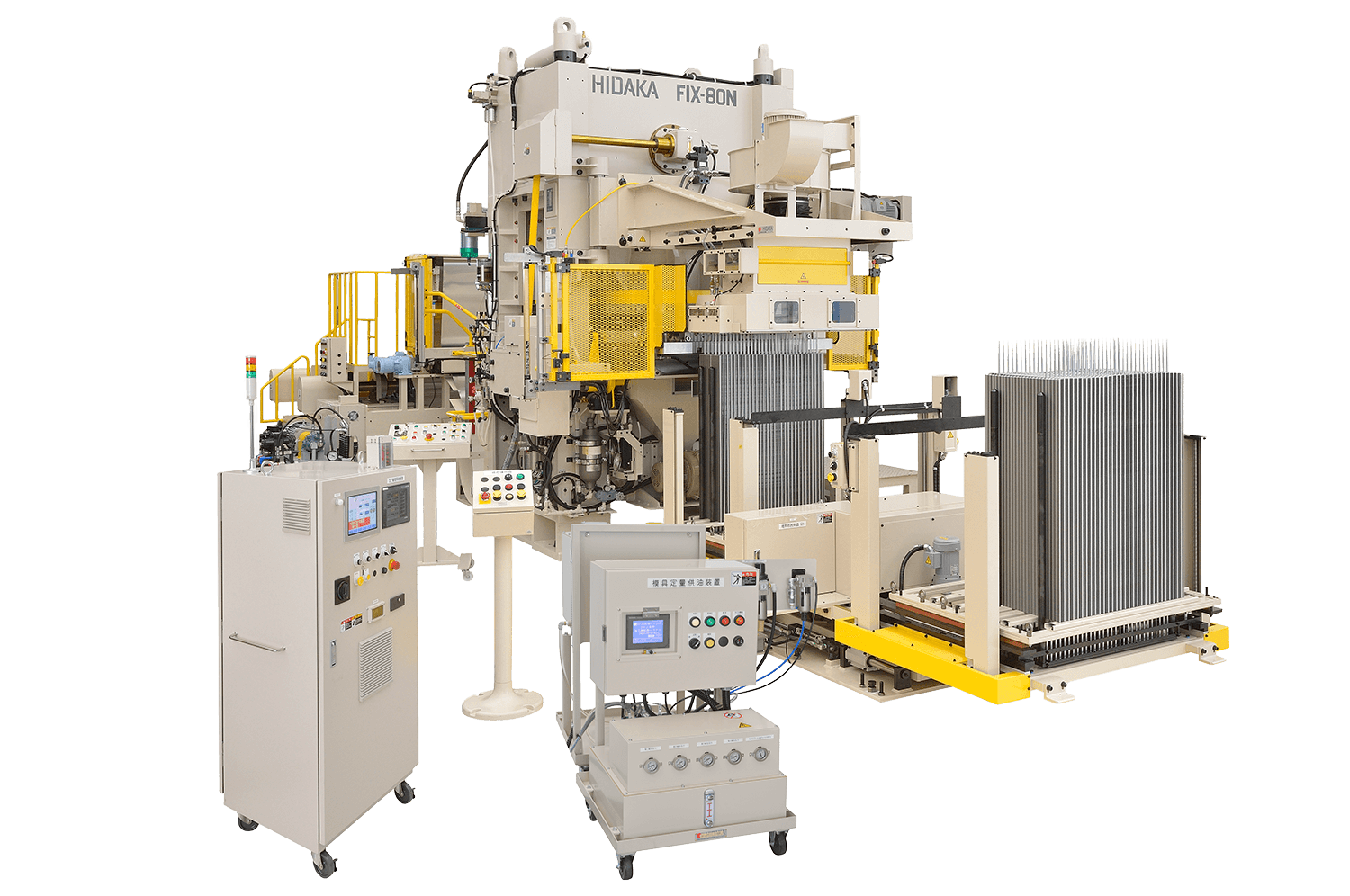

Standard Line

Standard model combining stability and robustness

The Standard Line features our FIX series presses as the core, adopting a structure designed to reduce setup time for various fin models and enhance equipment maintainability.

It excels as a high-mix production system.

The upstream and downstream line equipment can be freely arranged to suit your desired specifications, allowing for flexible configuration of the entire system.

Product Specifications

FIX-80N/100 Fin Press General Specifications

- Capacity:800/1000kN

- Stroke length:40/40mm

- Number of strokes:150-330/150-300SPM *1

- Slide adjust:30/50mm

- Die height:270/300mm

- Slide open:80mm

- Slide:1060×1300/1260×1300

- Bolster:1200×2000×140t *1

/1400×2100×140t *1 - Hitch feeder and gripper feeder

- Feed changer (function to change material feed length)

- Stamping oil supply system

- Stamping oil lubrication system

- Crank angle meter, SPM indicator, die height indicator

- Electronic cam control

- Load monitor(2ch)

- Anti-vibration system(optional)

- Control panel with large HMI

- Main unit handheld control panel

- Various safety equipment

- Output of various equipment operation data and maintenance data

*1: Subject to the specifications of the installed die.

*2: 4-channel type is optional.

Uncoiler Material Feeder

- Material coil outer diameter: 1200 mm max.

- Material coil weight: 2 tons max.

- Material coil mounting spindle: Single/double specifications are available.

For other special specifications, please contact us.

Fin Stacking Device

- 2-stage/3-stage swivel, fin assembly type

- Trolley-type fin stacking type

For other special specifications, please contact us.

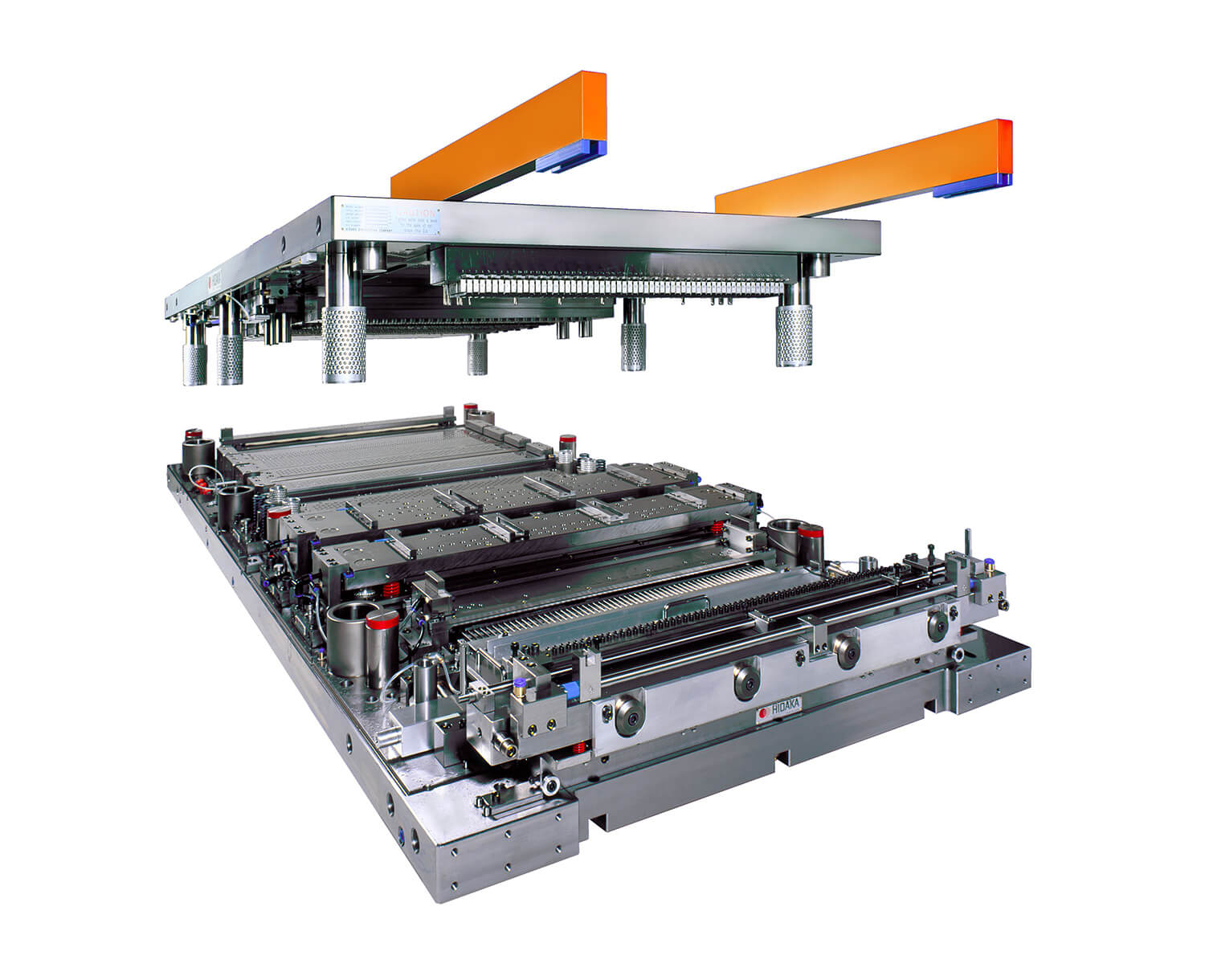

Compact General-Purpose Fin Press Line

Economy model suitable for high-mix production and high fins

The Standard Line features our FIX series presses as the core, adopting a structure designed to reduce setup time for various fin models and enhance equipment maintainability.

It excels as a high-mix production system.

The upstream and downstream line equipment can be freely arranged to suit your desired specifications, allowing for flexible configuration of the entire system.

Product Specifications

ES-50/ES-50L Fin Press General Specifications

- Capacity:500kN

- Stroke length:40 or 50 / 70 mm

- Number of strokes:150-330/150-270SPM *1

- Slide adjust:30mm

- Die height:270/260mm

- Slide open:80mm

- Slide:950×850

- Bolster:950×1650×120t *1

- Hitch feeder and gripper feeder

- Feed changer (optional)

- Stamping oil supply system

- Stamping oil lubrication system

- Crank angle meter, SPM indicator, die height indicator

- Electronic cam control

- Anti-vibration system (optional)

- Control panel with large HMI

- Main unit handheld control panel

- Various safety equipment

- Output of various equipment operation data and maintenance data

*1: Subject to the specifications of the installed die.

Uncoiler High-Speed Material Feeder

- Material coil outer diameter: 1200 mm max.

- Material coil weight: 1.5 tons max.

- Material coil mounting: Single/double specifications are available.

For other special specifications, please contact us.

Fin Stacking Device

- 2-stage/3-stage swivel, fin stacking type

- Trolley-type fin stacking type

For other special specifications, please contact us.

-

Research and Development

We continue to explore new fields by utilizing simulation technology with 3D CAD, digitization/visualization technology with CAE (3D analysis), and system control technologies such as line control.

Learn more

-

Quality Control

The quality and traceability of all products are controlled in accordance with ISO 9001, the international standard for quality management systems, and the products are subject to continual quality improvement.

Learn more