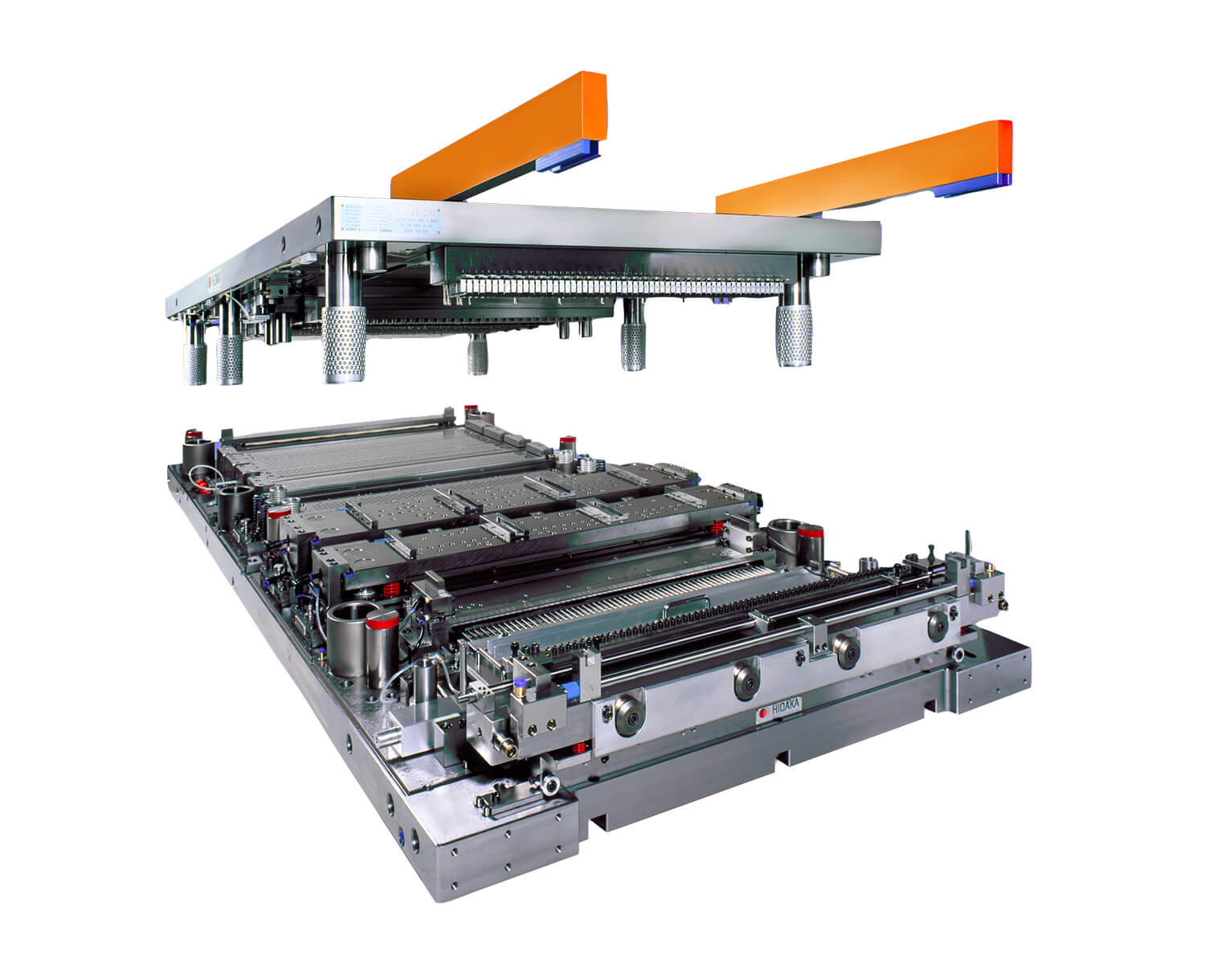

HIDAKA Fin Dies are produced through a combination of HIDAKA's high-speed progressive die design technology and ultra-precision machining technology that utilizes state-of-the-art machining equipment.

HIDAKA Fin Dies use a unique ironing process to quickly and stably produce high quality fins with high thermal efficiency.

各種のフィン形状、材料板厚/Various fin shapes, material thicknesses, and materials can be accommodated.

Fin Die

A fin die is used for manufacturing heat exchanger fins, which have a significant impact on the thermal efficiency of air conditioners and other equipment. HIDAKA's ultra-precision machining technology enables micron-level precision.

Product Features

-

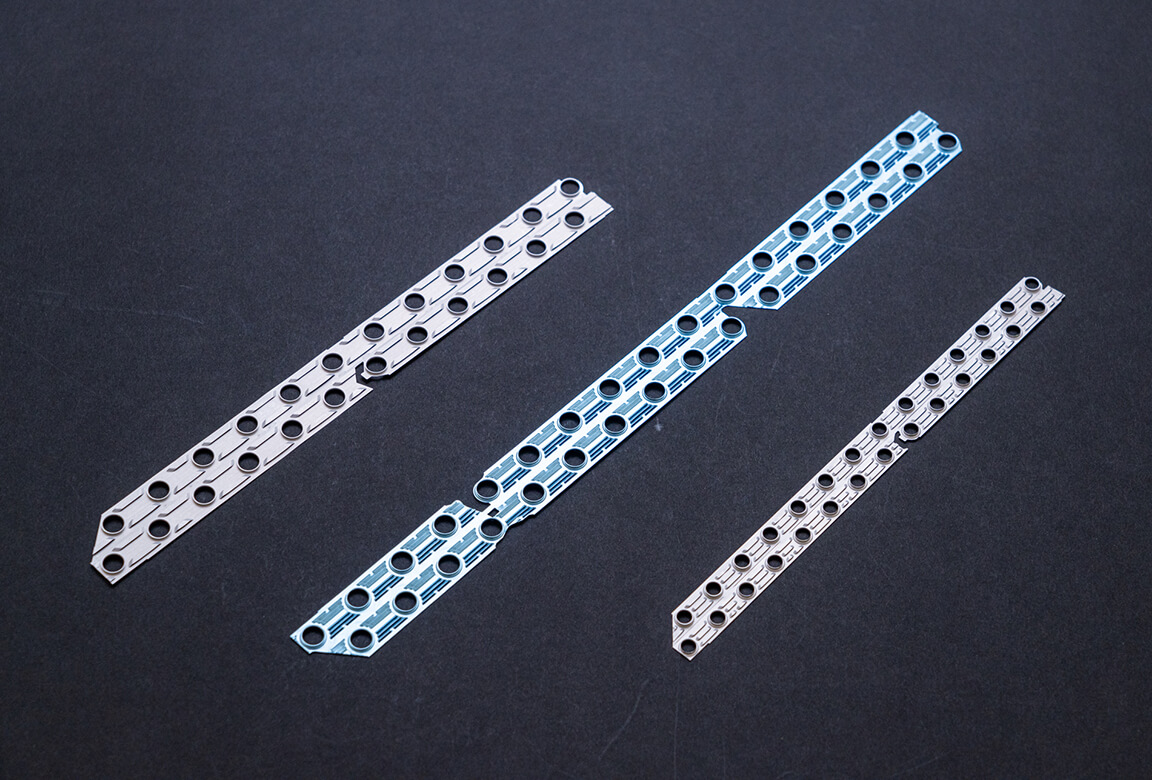

Indoor unit fins

Indoor unit fins are used in indoor unit heat exchangers. The shapes vary, as they are determined through research and development by air conditioner manufacturers. Flat fins are extremely rare. Most feature surface irregularities, such as ridges or slits, designed to increase the surface area that comes in contact with air.

They also often have notchings, but production speed is generally reduced due to decreased rigidity. Using HIDAKA Fin Die, however, high-speed production is possible even with surface irregularities and notchings.

-

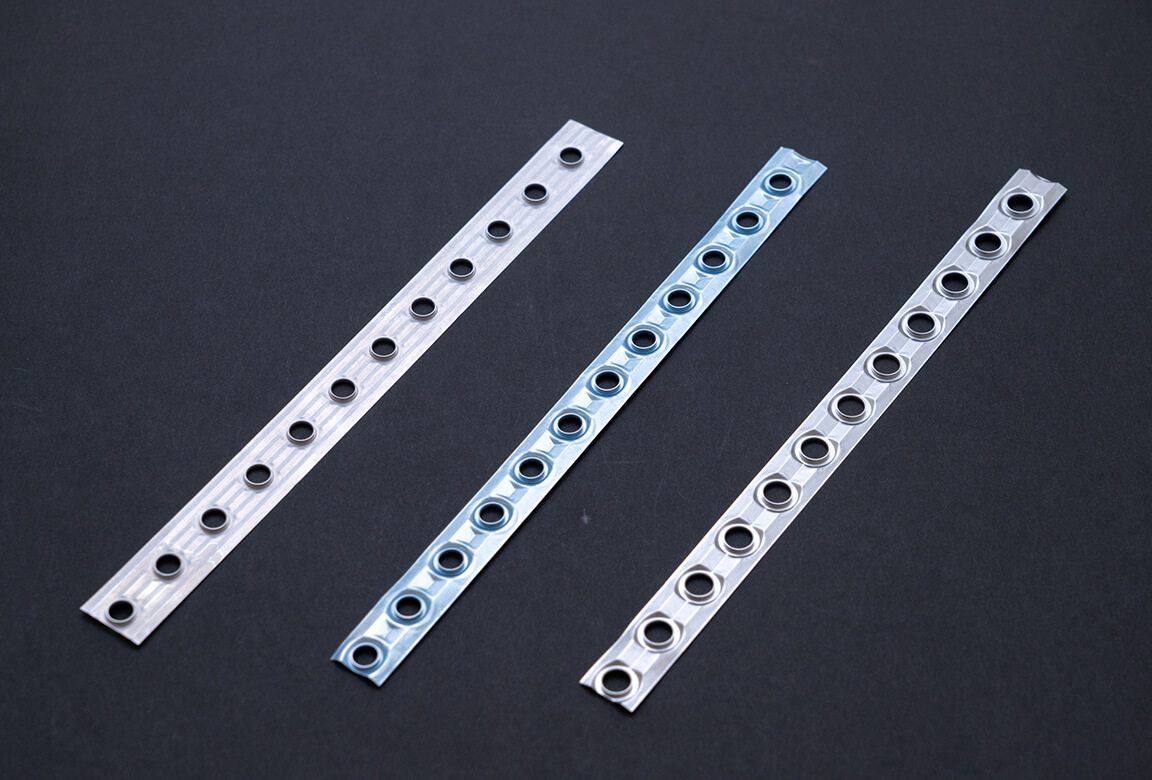

Outdoor unit fins

Most fins for outdoor unit heat exchangers also feature surface irregularities, but they have few slits or notchings. This is to prevent debris from getting into the slits and clogging them, since outdoor units are installed outdoors.

The forming of irregularities (corrugations) can easily cause distortion in the fins, potentially affecting production speed. With HIDAKA Fin Die, our years of experience and expertise enable us to anticipate such distortion in the design of the fins, enabling high-speed production.

-

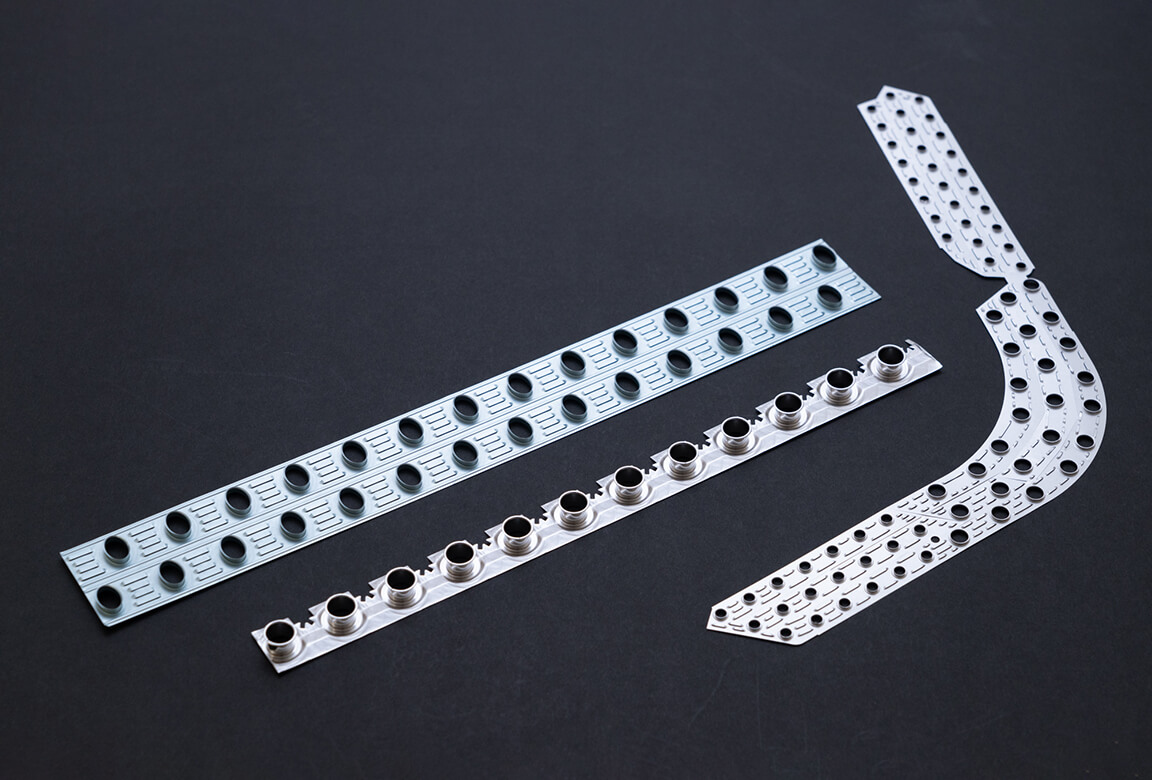

Special fins

HIDAKA Fin Die can also be used for various special fins, such as high fins with high color height, arc fins that are different from the usual strip shape, and oval fins with non-round pipe holes. Even if the shape appears challenging at first glance, we will actively explore ways to realize it. Please feel free to consult us anytime.

-

Research and Development

We continue to explore new fields by utilizing simulation technology with 3D CAD, digitization/visualization technology with CAE (3D analysis), and system control technologies such as line control.

Learn more

-

Quality Control

The quality and traceability of all products are controlled in accordance with ISO 9001, the international standard for quality management systems, and the products are subject to continual quality improvement.

Learn more