HIDAKA

Core Technology

Technical development/design/manufacturing of heat exchanger manufacturing systems

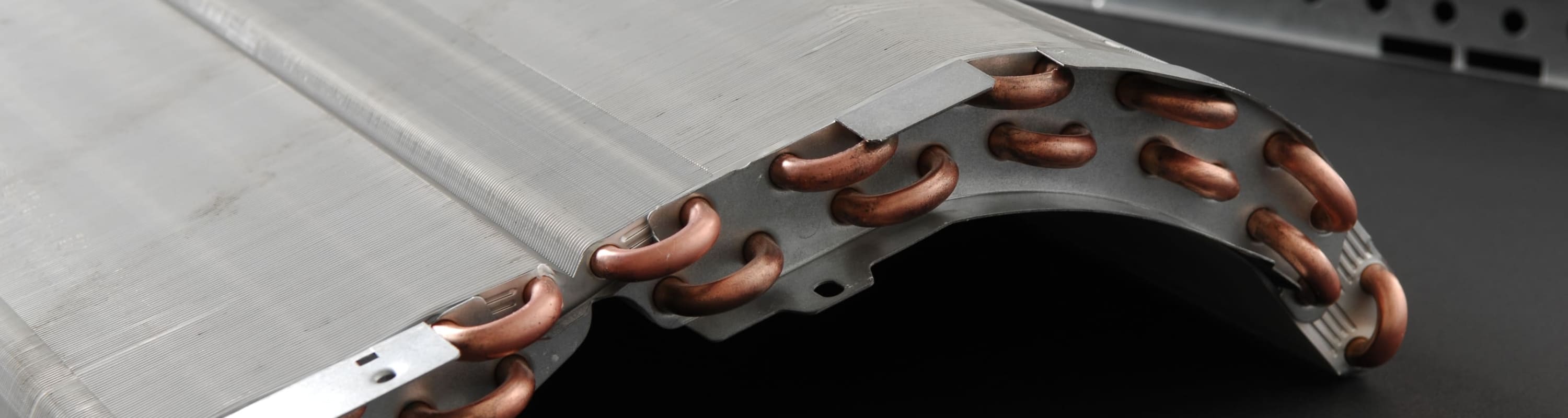

Heat exchangers: Units used to efficiently transfer thermal energy.

Widely used in everyday devices, such as air conditioners, refrigerators, vending machines, automobiles, and building air conditioners, these units are indispensable in our daily lives.

As a manufacturer specialized in the field of heat exchangers, with expertise in heat exchanger manufacturing systems and precision progressive dies for fin forming, HIDAKA has accumulated a wealth of technology and experience over 50 years.

We will continue to respond promptly to the challenges and various needs of the air conditioning industry, including those related to environmental performance.

For any inquiries regarding heat exchanger manufacturing systems, please feel free to contact us.

Achieving required performance and quality

At HIDAKA, we place great importance on listening to our customers’ needs and production methods, delving into their requirements, and deepening communication with them.

In the design phase, we leverage our accumulated experience and research expertise to repeatedly perform design reviews until we are satisfied, thereby refining performance.

In the manufacturing process, skilled technicians utilize state-of-the-art high-precision machine tools and inspection equipment in a factory environment maintained at constant temperature and humidity, performing machining and assembly with uncompromising precision.

Once a product is manufactured, it is thoroughly verified to ensure that it meets the performance and quality requirements of the customer. If further improvement is necessary, the design phase is revisited. In this way, the PDCA cycle for performance and quality is functioning within HIDAKA.

HIDAKA Fin LineHIDAKA Fin Line

With the addition of HIDAKA's unique system control technology, the system delivers even higher levels of performance in terms of production capacity, efficiency, and management.

HIDAKA Fin DieHIDAKA Fin Die

HIDAKA Fin Dies use a unique ironing process to quickly and stably produce high quality fins with high thermal efficiency.

-

Research and Development

We continue to explore new fields by utilizing simulation technology with 3D CAD, digitization/visualization technology with CAE (3D analysis), and system control technologies such as line control.

Learn more

-

Quality Control

The quality and traceability of all products are controlled in accordance with ISO 9001, the international standard for quality management systems, and the products are subject to continual quality improvement.

Learn more